Shanghai Weilin Information Technology Co., Ltd. is located in the

national city of Shanghai, factory area of 3000 square meters. Is a

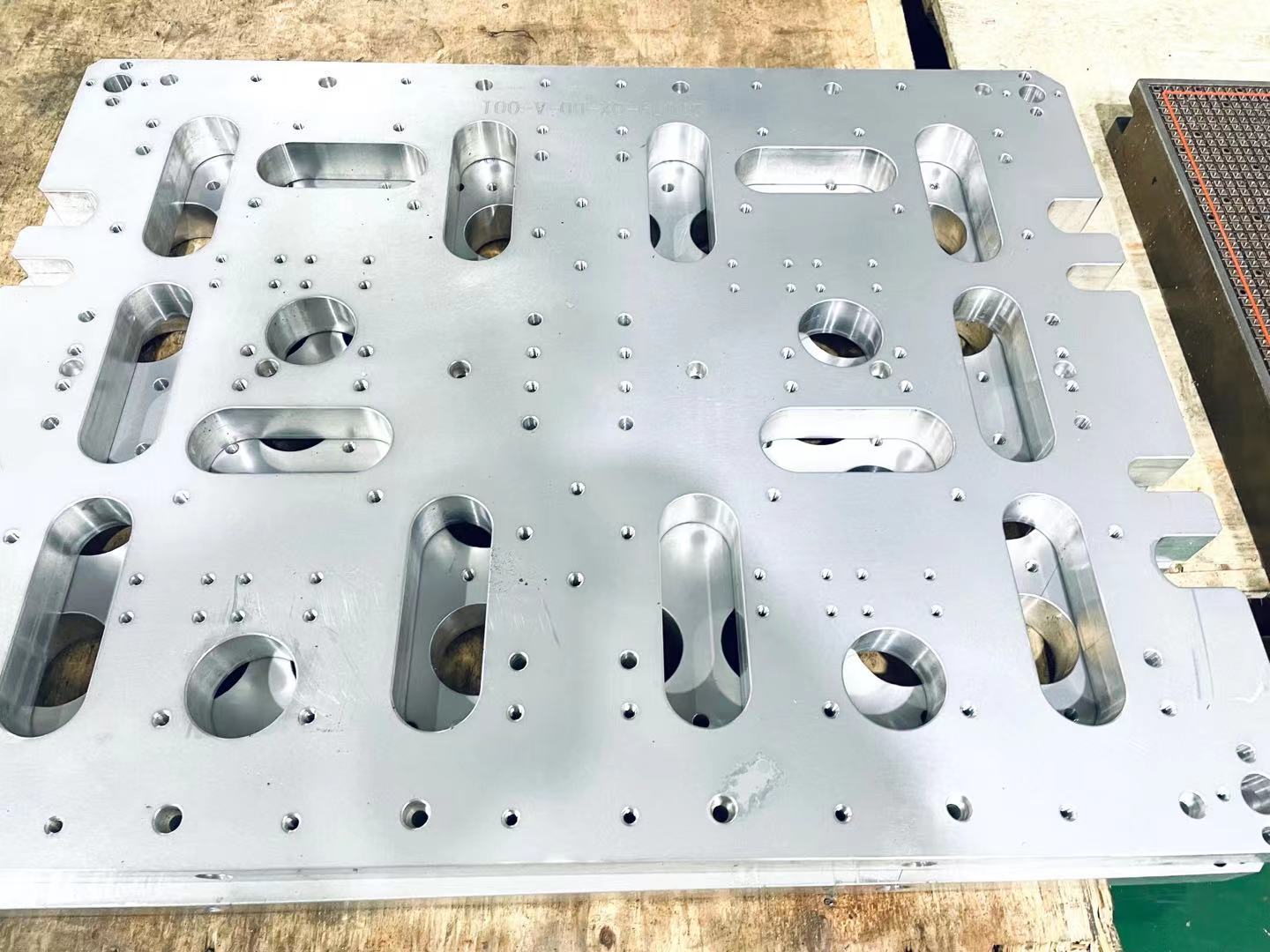

collection of high precision CNC machining, assembly, sales and

service in the integration of modern precision manufacturing

enterprises, the company has 10 years of experience in precision

metal parts processing, small feat machining tolerance, complex

structure and high precision parts and components, products widely

used in aviation, optics, medical, communications, power tools,

petrochemical and other fields.

Adhering to the business philosophy of "safety, environmental

protection, quality, efficiency, customer first, teamwork", the

company is the preferred machining supplier for many European and

American manufacturers and builds long-term strategic partnership.

Since the company since its inception, always adhere to the "full

participation, unity, innovation, continuous improvement, to

provide customers with satisfactory products and services" as

quality policy, from Germany, Japan, Switzerland, the introduction

of advanced CNC machining equipment and measuring equipment, the

aluminum alloy, copper alloy, stainless steel, carbon steel, alloy

steel and other materials processing has rich experience, at the

same time, we integrate industry resources, Effective use of

casting, forging, powder metallurgy, extrusion and other raw

material processing, to reduce the cost of mass production products

to the lowest; And cultivate a number of long-term cooperation in

surface treatment, heat treatment, spraying, dust-free cleaning and

other aspects of the partners, to provide customers with a full

range of products and services.

The production process of each product is decomposed into process

drawing, SOP and inspection specification. Effective quality

control for all aspects of production. Provide accurate dimensional

inspection report, material proof and heat meter treatment report

before each shipment.